Product Catalog

Contact

Title: Marketing Director

Email: andriy@tincpro.com

Mobile: +86 1390 1566 685

Tel: +86 512 5630 8506

Fax: +86 512 5630 8509

Zip: 215600

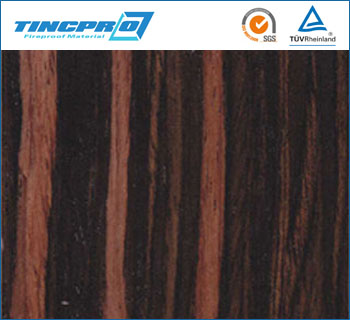

Seneca Prefinished veneered panel

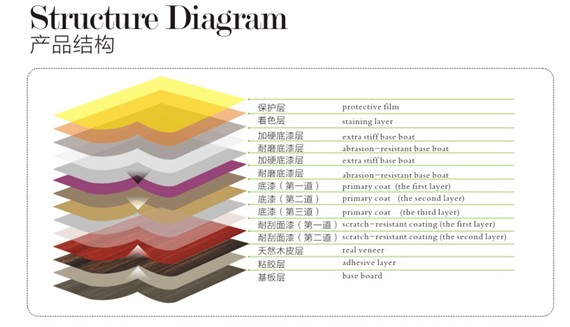

Prefinished veneer panel is composed of real veneer, substrate, abrasion resistant layer and UV resistant finish that are perfectly bonded together through innovative technology.

- Description

- Production line

- Installtion

- Application

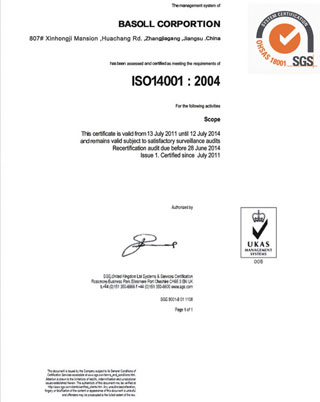

- Certificate

- Package

Description

Prefinished veneer panel is composed of real veneer, substrate, abrasion resistant layer and UV resistant finish that are perfectly bonded together through innovative technology. The surface is finished by high tech spraying and polishing.

Features :

1) Ecological material

FAS grade wood raw materials which is careful selected from the United states, brazil, Africa, Europe and other parts of the world ensure the quality of products. All raw materials are collected from forest with FSC certification which is an assurance that the wood you are using has been derived from sustainable forest management practices and no burden be made to natural environment.

2) Exquisite craftsmanship

With the State-of-the-art equipment, fist-class production process management, demanding process, the products are high quality. Lots of processes have applied for patents, and become the industry standard.

3) Beauty with fashion

We focus on aesthetic connotation and accomplish the perfect combination between nature and technology through inspiration of designers and design concept. Each product has been created with beauty and fashion through careful treatment.

4) Rich choices.

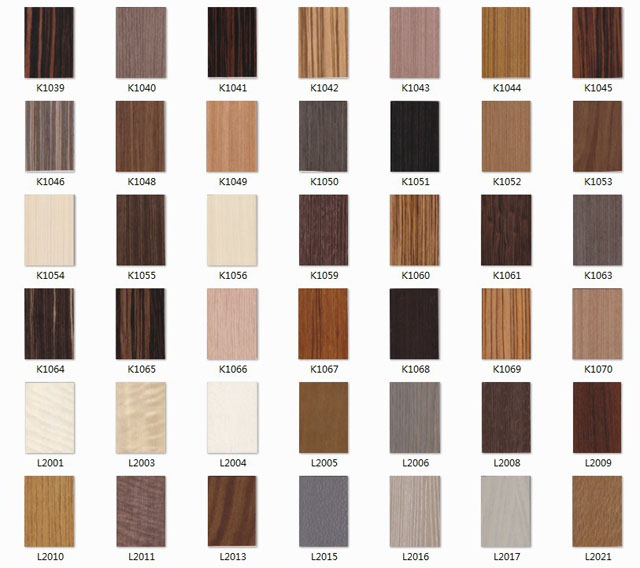

Based on the nature texture of wood and fused with designers superb artistic strokes, a great variety of wood surface products have been developed with different colors, shapes and textures.

5) Tine-saving

There is a great time and labor saving with our prefinished products and meanwhile eliminate the pollution caused by paint spraying.

6) Ease of maintenance.

Our products possess the characteristics such as scratch, abrasion, crack, and chemical substance resistance, and are easy for daily cleaning.

7) Green with no pollution

State-of-the-art 360 environmental management system, which from the choice of raw materials, production processing, waste disposal and other aspects strictly enforce environmental standards, ensuring green with no pollution products.

Technical data:

1) Bending radius: 60mm.

2) Weight per square meter: 2.2 kg.

3) Hardness: 750g>H.

4) Abrasion resistance(average values)EN 438-2.6:>150 Taber turns.

5) Stain resistance EN 438-2.15: No effect

6) Light fastness ( Xenotest ): >3 grey scale

7) Formaldehyde emission EN 717-2: E1

Specifications:

Nominal thickness: 3.0-5.0 mm.

Dimension :1220*2440mm.

Samples:

Patters showing:

1) Edge banding gluing

Contact adhesive(scrape the adhesive to be level).

2) Trim the diagonal line

Trim the finished edge banding with special trimming knife.

3) Sand diagonal line

Firstly sand the acute angle into round angle with 180 grit sandpaper, then sand until smooth with 400 grit sandpaper.

4) Mix and stir paint

Shake the paint bottle to mix the paint power and dissolvent sufficiently before application. And stir the paint to make the color even with paint brush.

5)Paint the diagonal line

Star to paint from the place 1 cm near the diagonal line.

6)Clean overflowed paint

Clean the overflowed paint with cloth before it dries; if there is still paint stain left after the paint dries, clean it with industrial alcohol.

Application area: residence, villa, commercial space, club, dining room, public venue, office.

Application type: wall panel, ceiling, pillar, moulding, door, furniture, etc.

|

packing

|

Inter packing: 0.2 mm plastic

|

|

Outer packing :bottom is pallets, covered with plastic film, around is carton or plywood, strength then by steel or iron 3*6

|

|

|

Quantity

|

20GP : 8 pallets/21M3

|

|

40GP: 16 pallets/42M3

|

|

|

40HQ: 18 pallets/53M3

|

- Economic Development Zone,Fuqian,Zhangjiagang City,Jiangsu Province,China

- Copyright © 2013 Basoll (Jiangsu) Corporation