Product Catalog

Contact

Title: Marketing Director

Email: andriy@tincpro.com

Mobile: +86 1390 1566 685

Tel: +86 512 5630 8506

Fax: +86 512 5630 8509

Zip: 215600

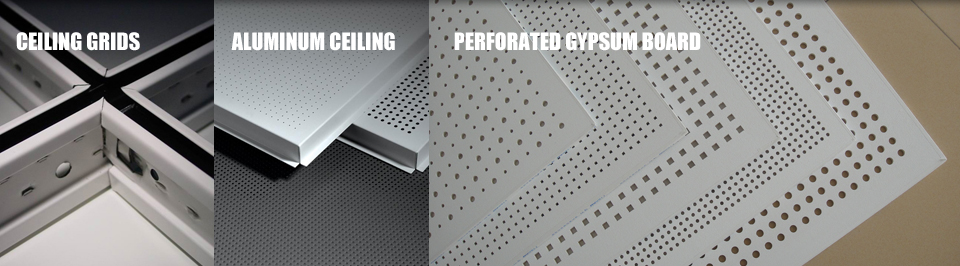

PVC PANELS

Light of weight, powerful strength, high intensity, heat insulation, flame resistant, corrode resistant, age resistant, no aspiration, easy cleaning, easy installing and so on

- Description

- Production line

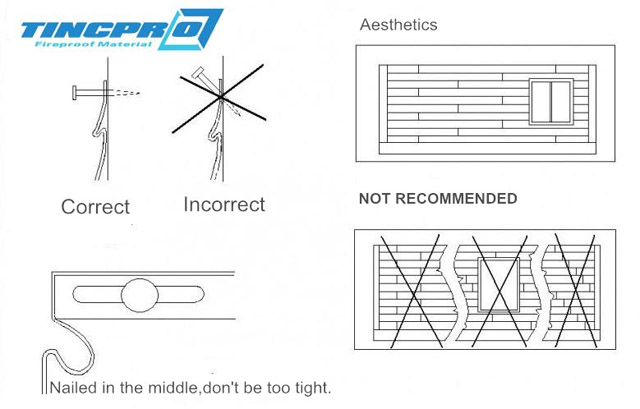

- Installtion

- Application

- Certificate

- Package

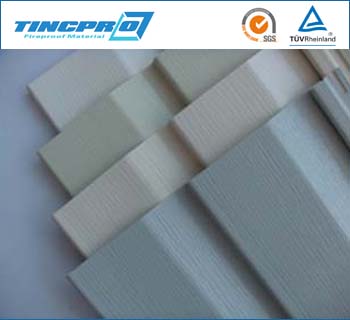

Introduction of PVC panel, PVC ceiling panel and PVC wall panel Description of product

| Main material | PVC (50%, 60%, 70%, 85% or as your request), Calcium Carbon and other chemicals 2 Acceptable |

|

Usual specification |

Length: customized size, such as 2.95m, 3m, 3.8m, 5.6m, 5.8m, 5.95m Width: 5cm to 40cm or customized Thickness: 5mm to 10mm or customized |

| Surface treatment | Oil print, hot stamping foil, thermal transfer print, laminated and so on as your pattern and color |

| Surface effect | Normal printing, thermal transfer printing (hot foil printed), peritoneal (laminated), high glossy, Pearl |

| Shape | Flat, groove panel |

| Production quality | Light of weight, powerful strength, high intensity, heat insulation, flame resistant, corrode resistant, age resistant, no aspiration, easy cleaning, easy installing and so on |

| Producing scale | With more than 60 PVC production lines and 100 kinds of moulds |

| Certificate | ISO9001: 2000, Soncap, Intertek certificate |

| Application | Hotels, commercial buildings, hospital, schools, home kitchen, bathroom, indoor decoration and so on |

| Sample | Free |

Product Features

1. Self-fire extinguishing, non-flammable.

3. It is impenetrable by insects or termites, and won’t rot or rust.

4. Resistance to weather/ special chemicals; Waterproof/ Washable.

5. The excellent rigid and superior impacted surface is without any peeling.

6. Natural wood grain: showing authentic wood structure and artistic sense.

7. Easy to be cut, drilled, nailed, sawed, and riveted. DIY is all right.

8. Quick maintenance and no need of painting.

9. The simple and fast installation can save a lot of time and manpower cost.

SPECIFICATIONS

|

Thickness(mm) |

Width(cm) |

Weight(kg/m2) |

|

6 |

18 |

1.8 |

|

5 |

20 |

1.6 |

|

6 |

20 |

1.8 or 2.0 |

|

6 |

25 |

1.8 or 2.0 |

|

6.75 |

25 |

2.4 |

|

7 |

20 |

2.0 or 2.3 |

|

7 |

59.5 |

2.5 |

|

7 |

60.3 |

2.5 or 3.0 |

|

7.5 |

25 |

2.4 |

|

8 |

20 |

2.5 or 2.625 |

|

8 |

25 |

2.3 or 2.5 |

|

8 |

16 |

3.125 |

|

8.5 |

20 |

2.5 or 3.5 |

|

9 |

20 |

3.0 or 3.15 |

|

9 |

30 |

2.95 or 3.085 or 3.16 |

|

9 |

25 |

3.2 |

|

9.5 |

30 |

3.9 or 4.0 |

|

9.5 |

10 |

3.5 or 4.0 |

|

9.5 |

16 |

3.3 or 3.75 |

|

9.5 |

20 |

2.625 or 3.5 or 3.75 or 4.125 |

|

9.5 |

6 |

5.3 |

|

11 |

20 |

4.4 |

|

12 |

15 |

3.0 |

|

12 |

20 |

3.9 |

|

13 |

20 |

4.375 |

|

15 |

20 |

4.75 |

|

Length: 5.8m for 20'GP and 5.95m for 40'HQ. or according to customer requirement. |

||

Production Capacity

| Product line name | Production Line Capacity | Actual Units Produced(Previous Year) |

| PVC Panel | 5,000,000m2 /Year | 4,500,000m2 |

| PVC Foam Profiles | 6000T/Year | 4800T/Year |

Export Market Distribution

| Market | Revenue (pevious Year) | Total Revenue (%) |

| Europe | Confidential | 46% |

| North American | Confidential | 34% |

| Mid East | Confidential | 10% |

| Southeast Asia | Confidential | 8% |

| Africa | Confidential | 2% |

Production Machinery

| Machine Name | Quantity | Condition |

| Mixing Machine | 7 | Acceptable |

| Extrusion Machine | 60 | Acceptable |

| Printing Machine | 3 | Acceptable |

| Hot Stamping Machine | 4 | Acceptable |

| Laminated Machine | 2 | Acceptable |

Used for ceiling and wall, as hotels, commercial buildings, hospitals, schools, cooking rooms, washing rooms and etc indoor decoration

Packing: PVC shrink-film, usually 10PCS/ bale or according to per customers' requirements

Delivery Lead Time: 10 days for 1X40'HQ.

- Economic Development Zone,Fuqian,Zhangjiagang City,Jiangsu Province,China

- Copyright © 2013 Basoll (Jiangsu) Corporation