Product Catalog

Contact

Title: Marketing Director

Email: andriy@tincpro.com

Mobile: +86 1390 1566 685

Tel: +86 512 5630 8506

Fax: +86 512 5630 8509

Zip: 215600

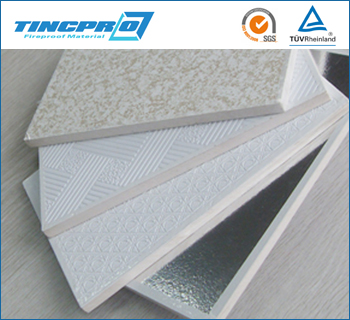

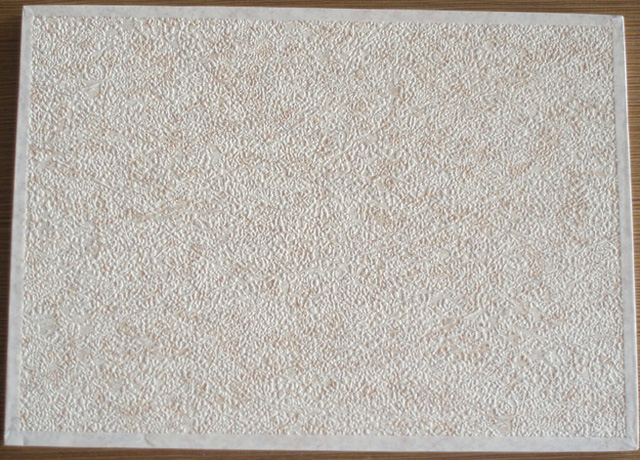

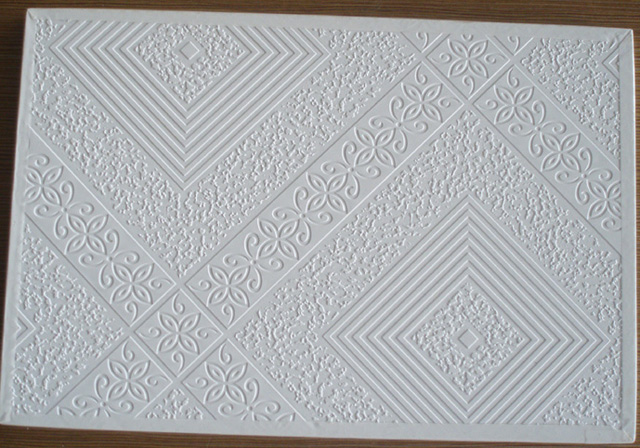

PVC-Faced Gypsum Ceiling Board

Good quality paper-faced gypsum board, surface is imported or domestic PVC film, back is aluminum Foil.

- Description

- Production line

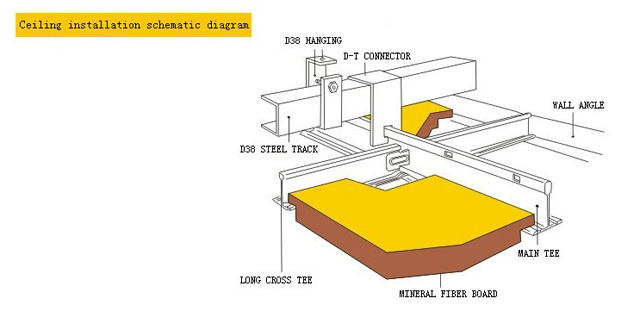

- Installtion

- Application

- Certificate

- Package

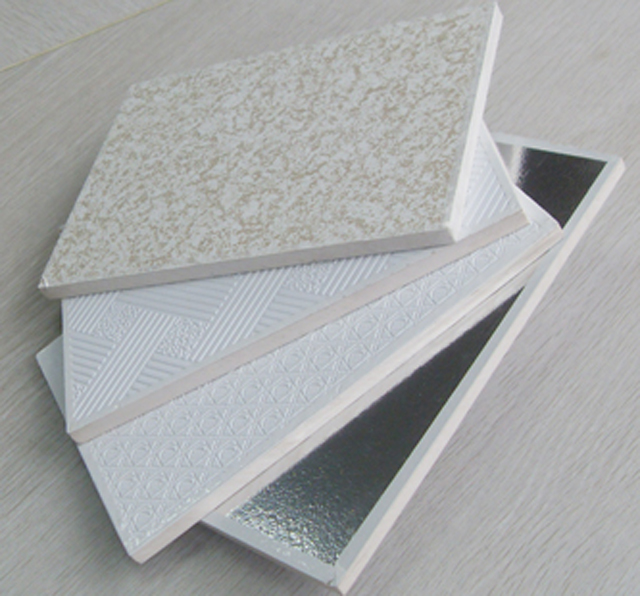

PVC Laminated Gypsum With Aluminium Foil back.

Size: (mm) 595x595 mm 600x1200 mm Thickness: (mm) 7.0 7.5 8.0 8.5 9.0 9.5mm

Certification: ISO, SGS

PVC Laminated Gypsum Ceiling Tiles/

PVC gypsum board/ PVC Laminated Gypsum Board/ Gypsum Ceiling

1 Material:

Good quality paper-faced gypsum board, surface is imported or domestic PVC film, back is aluminum Foil.

It s Made of high quality paper-faced gypsum board with a layer of PVC on surface and aluminum foil on back. (Gypsum, PVC and aluminum foil are all 100% environmental friendly materials with character of water proof and fire proof. )

2 Available Models and Specification

Size: (mm) 595x595 mm 595x1195 mm 600x600 mm 600x1200 mm

603x603 mm 603x1212 mm 605x605 mm 605x1210 mm

Thickness: (mm) 7.0 7.5 8.0 8.5 9.0 9.5

Designs: All kinds of designs available (Tell the pattern No. )

|

|

7.5mm

|

8mm

|

9mm

|

12mm

|

|

Weight(Kg/Sqm)

|

5.9

|

6.3

|

6.8

|

9.45

|

|

Quantity(Sqm/20’Gp)

|

3800

|

3600

|

3200

|

2000

|

|

Packing

|

8PCS or 6PCS in one carton, shrink plastic package.

|

|||

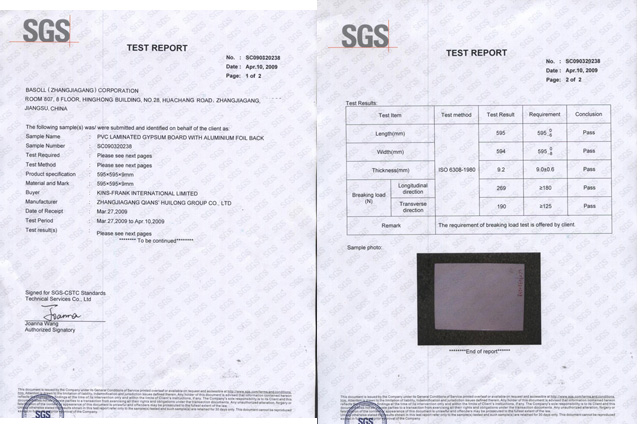

3 Certification

China national quality standard; ISO9001: 2000, ISO14001, SGS

4. TEST RESULT By SGS

|

Test Item

|

Test Method

|

Test Result

|

Requirement

|

Conclusion

|

|

|

Length (mm)

|

ISO 6308-1980

|

595

|

595 (0 -6)

|

PASS

|

|

|

Width (mm)

|

584

|

595 (0 -6)

|

PASS

|

||

|

Thickness (mm)

|

9.2

|

9.0 ±0.6

|

PASS

|

||

|

Breaking Load (N)

|

Longitudinal Direction

|

269

|

≥ 180

|

PASS

|

|

|

Transverse Direction

|

190

|

≥ 125

|

PASS

|

||

|

Remarks

|

The requirement of breaking load test is offered by client.

|

||||

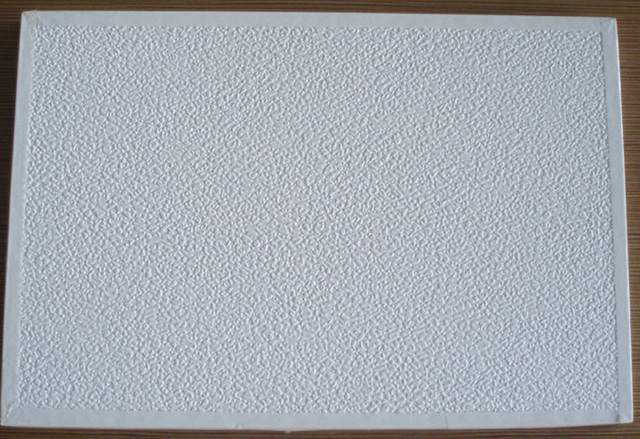

5. Function:

A). Environment protection product: Adopting natural gypsum material without any harmful material.

B). Non-flammable B1, in accordance with Chinese standard GB8624-1997

C). Heat retaining power

D). Sound insulating: Effectively solve sound insulation and fire proof.

E). Not deforming, not cracking: Keeping integrity and sound insulation for long under normal changes of.

F). Small expansion: Little coefficient of expansion, deforming under normal temperature.

G). Light weight, convenient to transport.

H). Special breathing performance, comfortable to live in.

I). Sunken proof...Non-dust, Easy clean...Good light reflection. Corrosion-resistant

6. Applications

It can be widely used in high fireproof and waterproof requirement environment, such as

hotel, hospital, school, house and factory etc.

|

Length( mm )

|

Width ( mm )

|

Thickness ( mm )

|

Edge

|

|

|

595

|

595

|

1195

|

7.0 8.0 9.0

|

Covered / Non-covered

|

|

600

|

600

|

1200

|

||

|

603

|

603

|

1206

|

||

|

605

|

605

|

1210

|

||

TRUSUS Gypsum ceiling tile is available to be produced the thickness from

7.0-12mm,the design according to customer requirements: Thickness 8.0-25mm.

Both Metric and Imperial systems are accept

|

SPECIFICATION

|

QUANTITY(Sqm)/20’GP

|

|

|

600*600 mm

|

9.5mm thick

|

3000

|

|

600*1200 mm

|

3000

|

|

|

600*600 mm

|

12.5mm thick

|

2500

|

|

600*1200 mm

|

2500

|

|

- Economic Development Zone,Fuqian,Zhangjiagang City,Jiangsu Province,China

- Copyright © 2013 Basoll (Jiangsu) Corporation