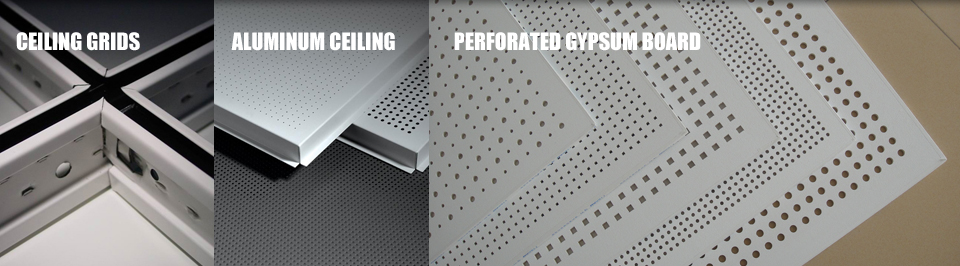

Product Catalog

Contact

Title: Marketing Director

Email: andriy@tincpro.com

Mobile: +86 1390 1566 685

Tel: +86 512 5630 8506

Fax: +86 512 5630 8509

Zip: 215600

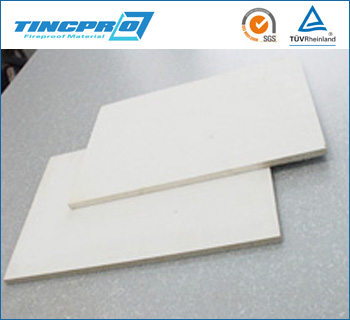

Waterproof MGO board

Magnesium Oxide Board is a technologically advanced building material that offers superior performance in every category when compared to traditional wood, gypsum and cement based products. Magnesium Oxide Board is virtually impervious to fire, water, insects; does not feed mold or mildew; is non-toxic, non- flammable and non-combustible; is durable, maintains it’s dimensional stability – even when wet; and has exceptional bonding surface.

- Description

- Production line

- Installtion

- Application

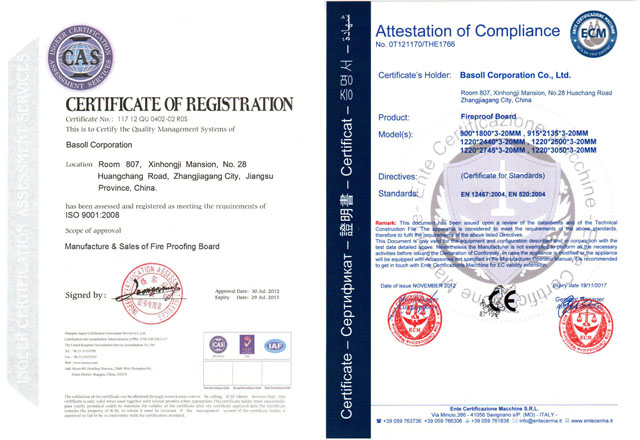

- Certificate

- Package

Description

Magnesium Oxide Board is a technologically advanced building material that offers superior performance in every category when compared to traditional wood, gypsum and cement based products. Magnesium Oxide Board is virtually impervious to fire, water, insects; does not feed mold or mildew; is non-toxic, non- flammable and non-combustible; is durable, maintains it’s dimensional stability – even when wet; and has exceptional bonding surface.

Ingredient table

|

Name

|

Figure

|

Proportion

|

|

Magnesium Oxide

|

|

46%

|

|

Magnesium Chloride

|

|

31%

|

|

Perlite

|

|

5%

|

|

Woodchip

|

|

14%

|

|

Fiberglass/Composites

|

|

4%

|

Features:

1) Fireproof and Waterproof (good performance of waterproof)

2) Light weight and High intensity

3) Sound insulation and Heat insulation

4) Heat preservation

5) Impact resistance

6) Cold resistance

7) Flexibility

8) Mothproof and anti-mildew

9) Environmental friendly

10) Easy to construction, maintenance

11) smooth surface, good appearance.

Technical data:

1) Non-flammability: grade A GB8624

2) Swelling rate:0.34% GA160-1997

3) Heating contraction: 1.2% GA160-1997

4) Water resistance: no condensation on the opposite side CNS13778

5) Impact resistance: does not crack or break CNS13788

6) Density: 0.95g/cm3 GB/T7019-1997

7) Dry bending resistance: 16Mpa GB/T7019-1997

8) Wet bending resistance: 22Mpa GB/T7019-1997

9) Sound insulation: ≥44 dB (GBJ121-88)

10) Heat-transfer coefficient: 0.14w/mk (GB/T 13475-92)

11) Installation: Easy to cut, saw, nail, stick, paint and veneer

12) Environmental friendly: Free of asbestos, formaldehyde

Specifications:

1) Size: 4'*8', 4'*9', 4'*10', others optional

2) Thickness: 3-12mm standard, others optional

3) Largest width: 1220mm

4) Maximum length: 3050mm

5) Color: white/grey

Samples

|

SAMPLES

|

SPECIFICATIONS

|

DEVIATION %

(PRIOR TO TEST) |

WEEK 1

DEVIATION % |

WEEK 2

DEVIATION % |

WEEK 3

DEVIATION % |

WEEK 4

DEVIATION % |

AVERAGE %

DEVIATIONS |

|

1

|

6 mm

|

103.17

|

100.48

|

101.13

|

101.45

|

101.45

|

100.90

|

|

2

|

8 mm

|

103.25

|

100.36

|

100.61

|

100.85

|

100.97

|

100.56

|

|

3

|

10 mm

|

103.00

|

100.10

|

100.29

|

100.49

|

100.49

|

100.27

|

|

4

|

12 mm

|

100.33

|

100.33

|

100.58

|

100.66

|

100.83

|

100.48

|

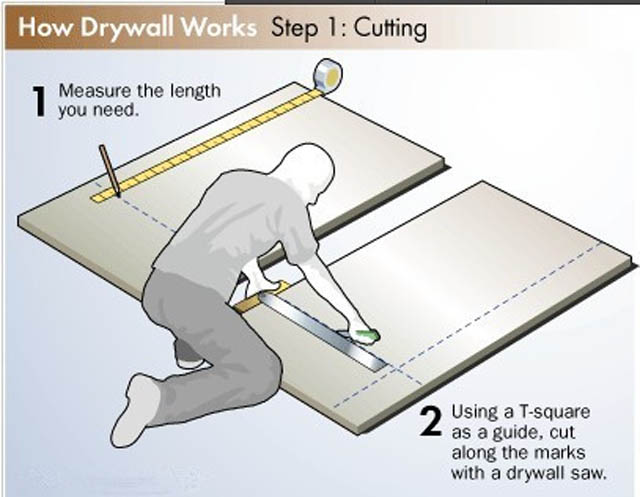

1. Cutting

Workers cut the board by knife when the machine send the board to the part, the machine will send the board to the next step after finished cutting.

2 Lifting

Workers lift the board to chassis when the board send to the end plate frame. Chassis must maintain two or more, we must leave time and space for repair board.

3 Curing gel

When magnesium fire board stack to a certain height it should be centrally stored indoors curing, the weather temperature reaches above 15 ℃ curing can be stored in the workshop, if below 15 ℃ insulation measures should be in a good health shop store cure.

4 Exposing board

When magnesium fire board has good strength freezing up exposing plates, Weather Temperature 5-10 ℃ , without heating 2 days, spring 10 ℃ -20 ℃ one day, in summer about 30 ℃ ,12 hours to expose boards.

5 Storage health

6 cutting head trimming

7 Quality Inspection and warehousing

Tincpro fireproof boards are mainly used in room, office building, hotel, market, hospital, airport ,subway, gymnasium, library, museum, theater, factory, building, computer laboratory, as interior wall system.

Function Board

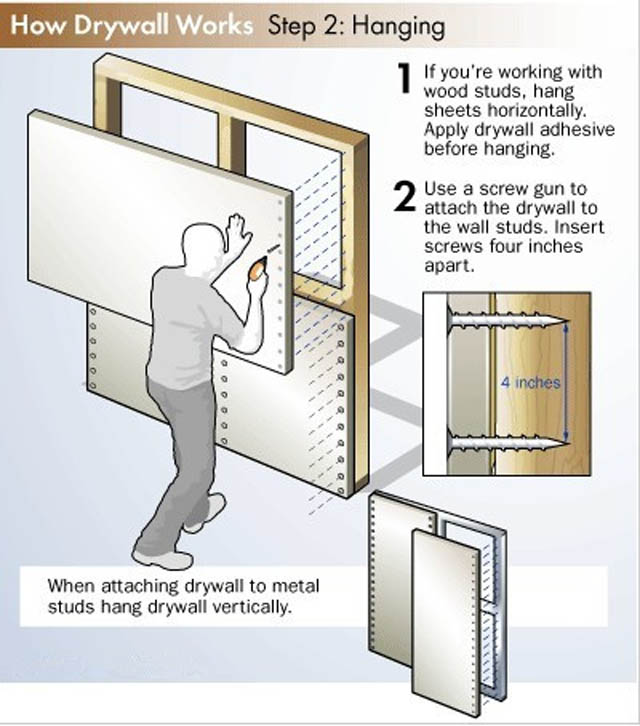

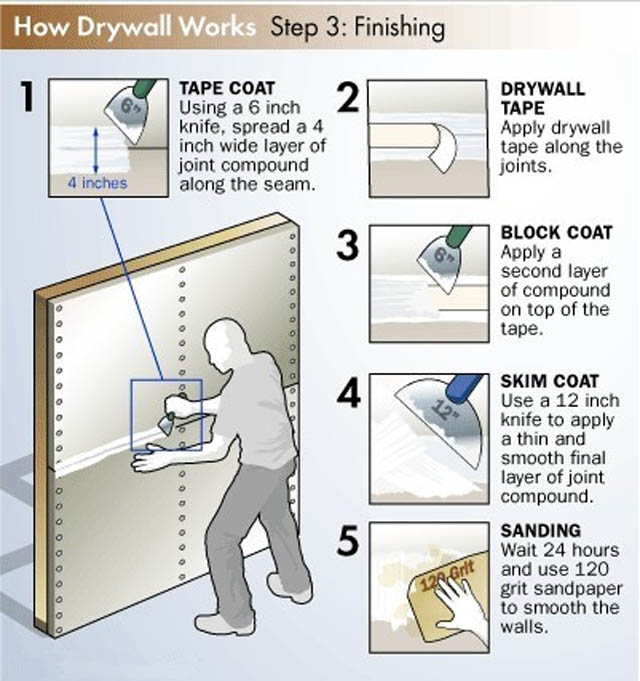

Tincpro Function board as standard MGO board, high quality MGO board and waterproof MGO board is used as base board, Normally is the main board of dry wall, Our board is eco friendly builder product and easy to install.

|

Specification

|

Loading quantity (PCS/20GP) loose packing

|

Loading quantity (PCS/20GP) packing in pallet

|

|

1220*2440*3

|

2600

|

300*6=1800

|

|

1220*2440*4

|

2000

|

225*6=1350

|

|

1220*2440*5

|

1600

|

180*6=1080

|

|

1220*2440*6

|

1300

|

150*6=900

|

|

1220*2440*8

|

1000

|

110*6=660

|

|

1220*2440*10

|

800

|

90*6=540

|

|

1220*2440*12

|

650

|

75*6=450

|

|

1220*2440*15

|

530

|

60*6=360

|

|

1220*2440*18

|

440

|

50*6=300

|

|

1220*2440*20

|

400

|

45*6=270

|

For other size, pls contact us.

Transportation:

When delivery , the boards should be piled up in the way of board-to board , then it is suitable for overseas transportation and indoor store .

The panels could not be stored outside or in the store near water . It must be stored in a smooth , no rain leaking , no dust and good ventilated warehouse .It should avoid moisture before used . Once it was affected with damp , it should be cleaned up right away and sent it to a well area for drying up. Otherwise it may be destroyed.

Carried by one man is prohibited . The board should be carried by two men with both hands of them and taking the long edges horizontally or taking the short edges vertically .

- Economic Development Zone,Fuqian,Zhangjiagang City,Jiangsu Province,China

- Copyright © 2013 Basoll (Jiangsu) Corporation