Product Catalog

Contact

Title: Marketing Director

Email: andriy@tincpro.com

Mobile: +86 1390 1566 685

Tel: +86 512 5630 8506

Fax: +86 512 5630 8509

Zip: 215600

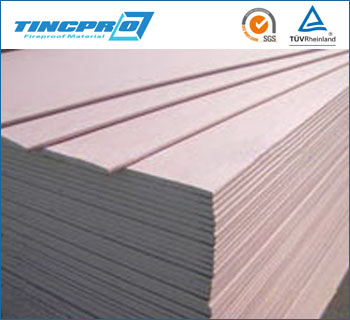

Fireproof Gypsum Board

It uses gypsum as the main material, adding fiber, bonding agents, modifiers, formed by suppressing, mixing and drying. It has the characteristics of fire sound insulation, heat insulation, light-weight, high-strength, small shrinkage, and the stability of small, non-aging, anti-moth-eaten.

- Description

- Production line

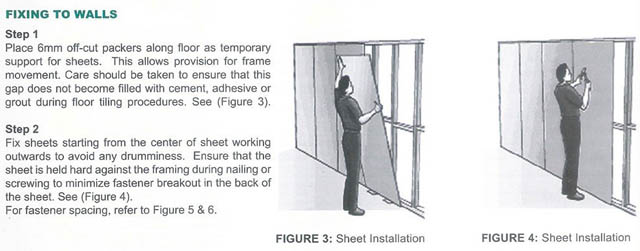

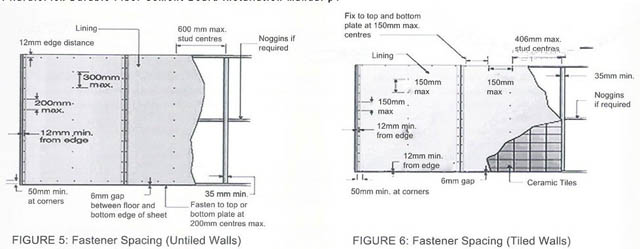

- Installtion

- Application

- Certificate

- Package

Description

It uses gypsum as the main material, adding fiber, bonding agents, modifiers, formed by suppressing, mixing and drying. It has the characteristics of fire sound insulation, heat insulation, light-weight, high-strength, small shrinkage, and the stability of small, non-aging, anti-moth-eaten. It can use nails, sawing, planning, adhesive and other methods of construction. It is widely used in ceiling, walls, interior walls,

Ingredient table

|

Name

|

Figure

|

|

Gypsum powder

|

|

|

Gypsum retaining paper

|

|

|

fiber

|

|

|

citric acid

|

|

|

starch

|

|

|

vesicant

|

|

|

others

|

|

Features :

1) Produced by advanced German technology and equipment using high-purity gypsum as the raw material, Tincpro fireproof board bears flat surface, accurate dimensions and assured quality.

2) The imported high-quality original wood pulp covering paper has smooth face and high strength.

3) High amount of alkali-free fire-resistant glass fiber is added to board core, about 5-6 times more than that of standard plasterboard. The alkali-free fire-resistant glass fiber has a softening temperature of over 1000°C, effectively improving the stability of plasterboard in case of fire.

4)The density of board core is 20% higher than that of standard plasterboard; in addition, certain amount of fire retardant is added to board core, thus improving its strength in high temperature.

5) Test shows that the partition system composed of Tincpro plasterboard and light-weight steel stud has a fire-resistant limit of up to 4 hours.

Technical data:

1)Weight per unit: 9.5mm: 8.3kg/m2.

12mm: 9kg/m2

15mm: 11.8 kg/m2

2)Rupture load: 9.5mm: Vertical: 513N.

Horizontal: 171N.

12mm: Vertical: 684N.

Horizontal: 213N.

15mm: Vertical: 781N.

Horizontal: 281N.

3)Inner irradiation ratio: ≤1.0

4)Outer irradiation ratio: ≤0.1

5)Fire resistant temperature: 1000°C.

Specifications:

Standard size: 1200*2400mm

Length :1800mm to 3600mm

Width :1200mm&1220mm

Thickness :7mm to 15mm

Edge :Square Edge and Tapered Edge

Samples:

1 Ingredients section

2 Forming section

3 Drying section

4 Trimming , stacking section

5 Decorative veneer section

- Widely used for partition systems and lining systems in civil, commercial and industrial buildings

|

Specification

|

Loading quantity (PCS/20GP) loose packing

|

Loading quantity (PCS/20GP) packing in pallet

|

|

1200*2400*8

|

1000

|

120*6=720

|

|

1200*2400*9

|

880

|

106*6=640

|

|

1200*2400*10

|

800

|

96*6=576

|

|

1220*2440*12

|

680

|

80*6=480

|

For other size, pls contact us.

When delivery , the boards should be piled up in the way of board-to board , then it is suitable for overseas transportation and indoor store .

The panels could not be stored outside or in the store near water . It must be stored in a smooth , no rain leaking , no dust and good ventilated warehouse .It should avoid moisture before used . Once it was affected with damp , it should be cleaned up right away and sent it to a well area for drying up. Otherwise it may be destroyed.

Carried by one man is prohibited . The board should be carried by two men with both hands of them and taking the long edges horizontally or taking the short edges vertically

- Economic Development Zone,Fuqian,Zhangjiagang City,Jiangsu Province,China

- Copyright © 2013 Basoll (Jiangsu) Corporation