Product Catalog

Contact

Title: Marketing Director

Email: andriy@tincpro.com

Mobile: +86 1390 1566 685

Tel: +86 512 5630 8506

Fax: +86 512 5630 8509

Zip: 215600

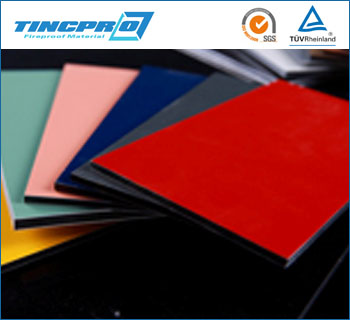

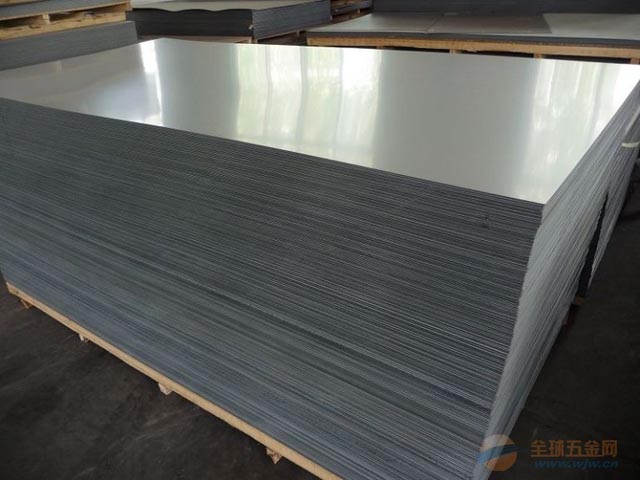

Aluminum Composite Panels

TINCPRO aluminum-plastic panels are made of quality antirust alloy sheets and high Intensity polyethylene core sheets, all coated with the most world advanced fluorocarbon resin, and strictly manufactured in accordance with international standard process.

- Description

- Production line

- Installtion

- Application

- Certificate

- Package

Description

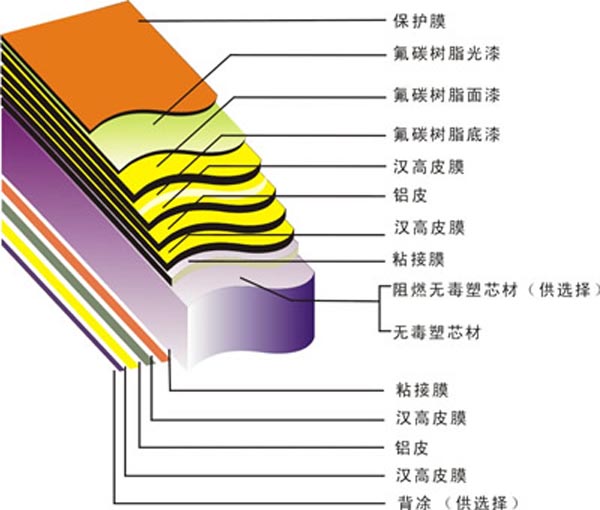

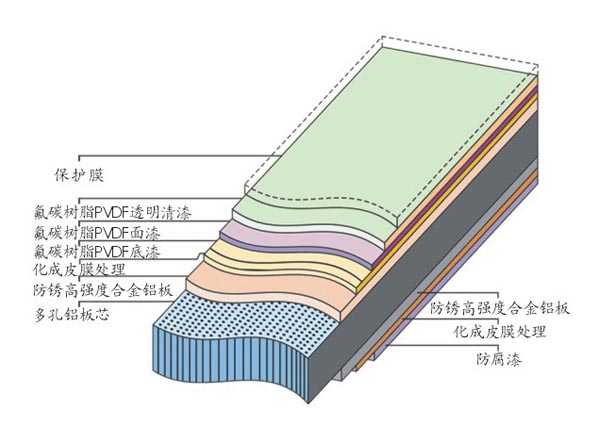

TINCPRO aluminum-plastic panels are made of quality antirust alloy sheets and high Intensity polyethylene core sheets, all coated with the most world advanced fluorocarbon resin, and strictly manufactured in accordance with international standard process. Thanks to the use of excellent raw materials and the most advanced manufacturing process, our aluminum-plastic panels are given super weather, resistance to maintain sound quality despite terrible weather conditions. The thickness and color difference in surface are evenly arranged and panel. Flatness is fairly good.

Materials:

• Front side: aluminum roll coated with PVDF or polyester

• Core: fire-resistant polyethylene

• Rear side: aluminum coated with polyester

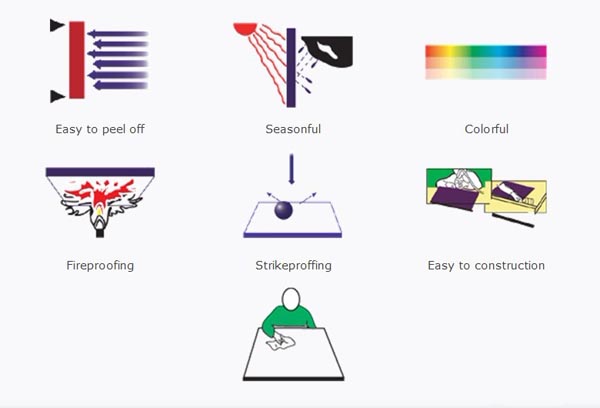

Features:

• Super peeling strength

• Excellent surface flatness and smoothness

• Superior weather, corrosion and pollutant resistance

• Even coating, various colors

• Fireproof, excellent heat and sound insulation

• Superior impact resistance

• Lightweight and easy to process

• Easy to maintain

|

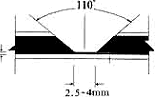

Saw Incision Method: |

|

|

Fretsaw: trapezoidal / flat saw blade Incline the teeth of flat saw 45° hard alloy.

The diameter of saw blade: 300mm

Number of saw teeth: 72 pieces are used to cut 5 boards. Leuco Ref: 188389

96 pieces are used to excision the fins.

Leuco Ref: 188390

The diameter of saw blade: 250mm

Number of saw teeth: 60 pieces are used to cut 5 boards. Leuco Ref: 188939

80 pieces are used to excision the fins Leuco Ref: 188940

Thickness of teeth: 3.0mm

Back angle: 15°

Front angle:+10°

|

|

| V- Notch Method: | |

|

If you want make V-slot in the back of the aluminum composite panel, through the artificial method is easy to mold, use the regulate planer.

Incision rate : 3000-5000 meter/ min

Feeding rate: 25-30 meter/ min |

|

| U-Notch Method: | |

|

Using the special incision machine with guide board to make U-notch.

After the process of V-notch, the aluminum composite panel is very easy for hand operation. |

|

| Riveted joint Method: | |

| Using the usual equipment can rivet and solid fixed, if used outside, the use of heating seals should be taken into consideration. Self-plugging rivet can connect conveniently from one direction. |

|

|

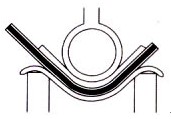

Bending:

|

|

|

Operating on flat roof, the bending part can be made very trim. Flat punch, table-flap machine or bending mould are suitable to be the bending equipments. We recommend you to bend with the temperature above 10°C.

|

|

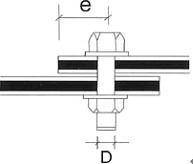

| Bolt connection: | |

| Concerning the distortion limitation, Company e≥2D, hole diameter(D) and the distance between the center of the hole and panel edge(e), is the best calculate method. |  |

| Using the table-flap: | |

| Using the table-flap, the min inside radius: r=15xt (t means thickness of the panel) |  |

| Using trio-press brake: | |

| Comparing to the bable-flap machine, the trio-press brake is fitter for bigger inside radium bending. And if you do it before bending, it can be bended by hand after bending. |

|

| Drilling Method: | |

|

It is easy to drill holes on Aluminum composite panel, in order to realize the best effect; we suggest you use special aluminum and plastic drilling machines.

Incision angle: 100°- 400°Helical angle: 30°- 50° Incision rate:50-300 meter/min Feeding rate: 0.02-0.5mm/Speed Drilling dimension: screw width +2mm |

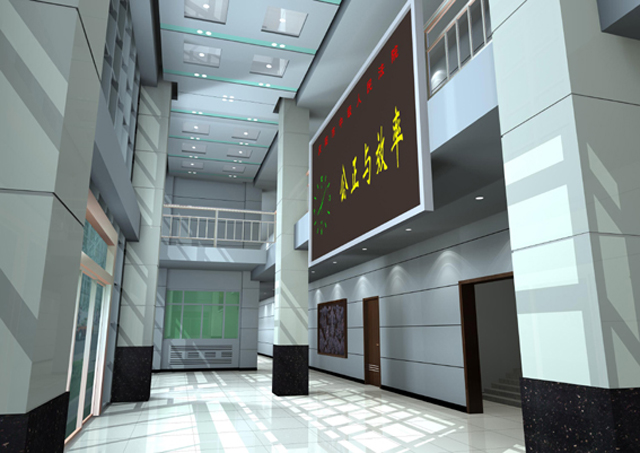

• Wall and interior decoration of air fields, docks, stations, metros market place,

hotels, restaurants, recreation places, top-grade residence, villas, office, etc.

• Big billboards, shop windows, roadside news kiosks, bookstalls, telephone booths, traffic sentry boxes and filling stations.

• Internal walls, ceilings, compartments, kitchens, toilets, and basement dado.

• Shop decoration, interior layers, storied cabinet, pillar and furniture.

• Decoration for boxes in trains, automobiles, ships and carriages.

• Renovation and reconstruction of old buildings.

• Cleaning and dust control projects.

Wooden pallet or in bulk

Aluminum Composite Panel

|

Surface

coating

|

Standard size

Width x Length

(mm)

|

Thickness

(mm)

|

Aluminum

Sheet

Thickness

(mm)

|

20 foot container (M2)

|

|

PE

|

1220 x 2440

|

3

|

0.12

|

4100

|

|

PE

|

1220 x 2440

|

3

|

0.15

|

4100

|

|

PE

|

1220 x 2440

|

3

|

0.21

|

4100

|

|

PE

|

1220 x 2440

|

3

|

0.25

|

4100

|

|

PE

|

1220 x 2440

|

3

|

0.30

|

4100

|

|

PE

|

1220 x 2440

|

4

|

0.12

|

3100

|

|

PE

|

1220 x 2440

|

4

|

0.15

|

3100

|

|

PE

|

1220 x 2440

|

4

|

0.18

|

3100

|

|

PE

|

1220 x 2440

|

4

|

0.21

|

3100

|

|

PE

|

1220 x 2440

|

4

|

0.25

|

3100

|

|

PE

|

1220 x 2440

|

4

|

0.3

|

3100

|

|

PE

|

1220 x 2440

|

4

|

0.35

|

3100

|

|

PE

|

1220 x 2440

|

4

|

0.40

|

3100

|

|

PE

|

1220 x 2440

|

4

|

0.45

|

3100

|

|

PE

|

1220 x 2440

|

4

|

0.5

|

3100

|

|

PVDF

|

1220 x 2440

|

4

|

0.25

|

3100

|

|

PVDF

|

1220 x 2440

|

4

|

0.30

|

3100

|

|

PVDF

|

1220 x 2440

|

4

|

0.35

|

3100

|

|

PVDF

|

1220 x 2440

|

4

|

0.40

|

3100

|

|

PVDF

|

1220 x 2440

|

4

|

0.45

|

3100

|

|

PVDF

|

1220 x 2440

|

4

|

0.50

|

3100

|

The other size:

1) Width: Maximum width is 1,575mm; Other widths available upon request

2) Length: 2,440mm (standard); Up to 6,000mm (recommended)

- Economic Development Zone,Fuqian,Zhangjiagang City,Jiangsu Province,China

- Copyright © 2013 Basoll (Jiangsu) Corporation